Communications Services Provider Assesses Disruptive Technology Impacts

Future Proof Computing Lives at the Edge

Industrial Manufacturer Leverages Digital and Industrial Internet of Things (IIoT) Technologies To Increase Productivity and Become More Customer Responsive

Description

Our client, an industrial materials and processing business with 40+ plant locations reached out to Harbor initially to seek assistance in helping to raise the leadership team’s awareness of Industrie 4.0, digital and IIoT technologies.

Challenge

After initial discussions with the leadership team, it became clear that the company wanted to significantly increase customer service levels by reducing the subjective nature and overly manual processes in their operations. Leadership’s goal was to re-think operations practices and processes and utilize IIoT and digital technologies to help inform a much higher level of customer responsiveness.

Process and Outcomes

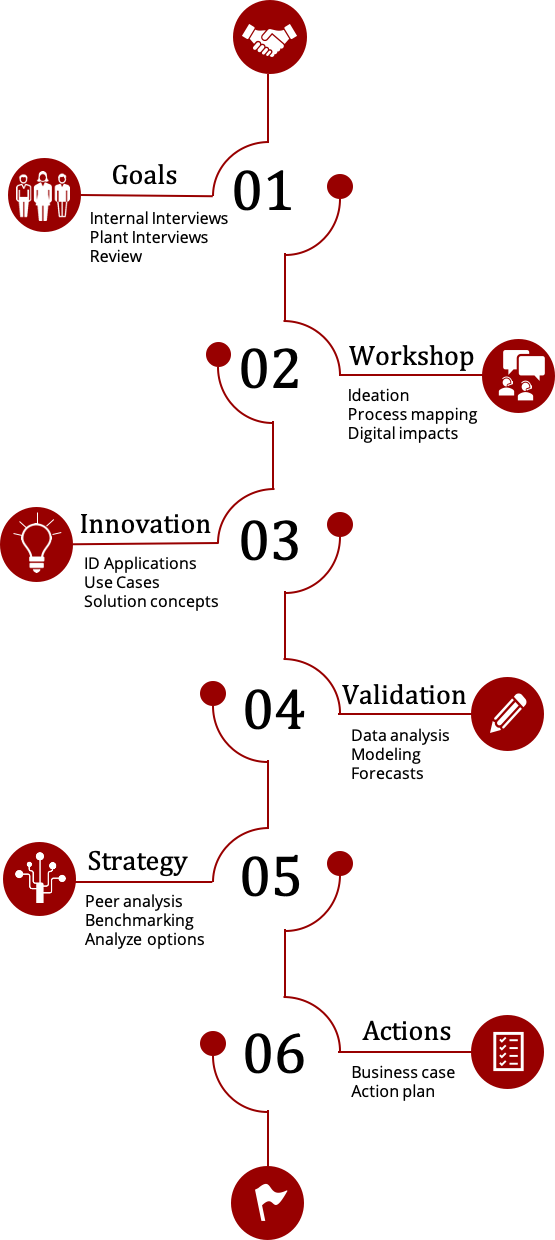

We conducted interviews with stakeholders to determine the most critical near term needs and requirements as well as to identify the biggest hurdles preventing new technology adoption. We then facilitated multiple stakeholder innovation workshops to help better understand how new technologies have, in the past, been successfully (or not) integrated into operations.

Based on these interactions, we determined that the best approach would be to pilot a master operating platform for all plants (40+ facilities) in a target plant first, including:

- Dynamic machine and production monitoring, control, and automation

- Real-time product visibility

- Digital order entry, order life-cycle tracking, and automated invoicing

Successfully piloting and integrating new digital and IIoT technologies with existing systems helped eliminate defaulting into a “rip-and-replace” implementation approach. This set the stage for the pilot program to utilize several advanced technologies to optimize & automate operations and become a showcase to the company’s peer plants helping to demonstrate this initiative was less about eliminating jobs and more about improving processes.

Impacts

By investing in a next generation operations platform and data architecture, our client has significantly upgraded capabilities in their materials processing operations and established a blueprint for plant roll outs and future innovations.

The company has realized significant improvements in throughput, raw materials utilization, on-time deliveries and customer satisfaction. The master plant program is being rolled out to over 20 facilities and, where it has been implemented, it has increased quality levels, resource management and utilization ultimately leading to an early increase in customer service levels and improved operating profits at each plant.

CLIENT

Global leader in galvanizing and materials processing

DELIVERABLES

Technology Tracking

Innovation Workshops

Technology Opportunity Assessment

Opportunity Validation

Growth Strategy Development